Welcome to Shandong Kexing Chemical Co.,Ltd.

Website Wechat

Wechat

Welcome to Shandong Kexing Chemical Co.,Ltd.

Website Wechat

Wechat

Catalysts, gasoline anti-explosion agents, antioxidants, oil slurry scale inhibitors, etc.

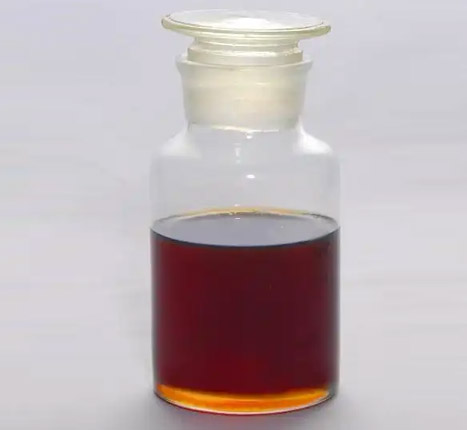

Gasoline anti-explosion agent

1. Increase the octane number of gasoline. Add one ten thousand MMT to gasoline. The manganese content does not exceed 18 mg/L, which can increase the octane number of gasoline by 2 to 3 units.

2. Improve automobile power and reduce fuel consumption. The engine frame test of the Ministry of Transportation Automobile Transportation Industry Energy Utilization Monitoring Center shows that compared with MMT-free gasoline, the engine power performance is improved and fuel consumption is reduced.

3. Good coordination with oxygen-containing components such as MTBE and ethanol. MMT has good adductivity with MTBE and ethanol in terms of improved octane number, which provides convenience for the production of high-grade gasoline. It can meet a higher octane number, and avoid excessive reduction in vehicle power performance due to excessive use of MTBE, and can meet the national standard of "oxygen content not exceeding 2.7%.

4. Reduce pollutant emissions in automobile exhaust. Compared with 90# unleaded gasoline with MMT, CO in engine exhaust decreased by 17.7% and HC decreased by 18.2%.

5. It has an effect on the catalytic converter of automobile exhaust gas. Phosphorus is a well-known catalyst toxin. When MMT is burned, it can remove phosphorus and reduce sediments on the catalyst. Therefore, the fuel using MMT can extend the life of the catalyst, keep the catalyst high conversion rate, thereby more effectively converting harmful gases and reducing pollutant emissions.

Oil slurry scale inhibitor

1. It has a good dispersion effect on the insoluble suspended substances inherent in the oil slurry (such as catalyst fine powder, accounting for about 50% of the scale composition) to prevent its condensation and deposition.

2. Chemical reactions to prevent scale. The polymerization reaction for scale formation achieves the effect of terminating chains to increase the reaction by forming inert molecules (i.e., saturated radicals). By passivating the pipe wall of the oil slurry heat exchanger, the corrosion resistance of the metal surface is enhanced, etc. 3. It can both prevent and remove scale. Within the normal operating temperature range at the bottom of the fractionation tower, the formation of scale and precipitation can be effectively suppressed, and there is no adverse effect on the distribution of catalytic cracking reaction products. It can maintain the long-term stable operation of the oil slurry system equipment and pipelines, reduce energy consumption, improve the device operation efficiency and economic benefits of the refinery.