Flowable heavy oil cold production continuous viscosity reduction foaming flooding activator SDKX-66

Flowable heavy oil cold production continuous viscosity reduction foaming flooding activator SDKX-6669

heavy oil cold production product innovation point: SDKX-6669 has dual functions of foaming and viscosity reduction under different oilfield reservoir temperatures, continuous viscosity reduction without rebound . Stability is better than conventional viscosity reducers.

2. In the synthesis of SDKX-6669 product, the supermolecular viscosity-reducing active agent is used to graft the foaming tube energy group, which innovates both viscosity reduction and high foaming, which is suitable for heavy oil cold production air foam flooding, ensuring foam regeneration and performance The continuity and stability of the viscosity reduction system

3. The innovation of the SDKX-6669 product is to reduce the viscosity of Xinjiang oilfields with high temperature, high salinity, high salinity flowing heavy oil, and extra-heavy oil blocks mixed with thin oil, as well as conventional wellbore viscosity reduction. The difficult problems of fast viscosity reduction and fast viscosity rebound have synthesized a product that can continuously reduce viscosity without rebounding.

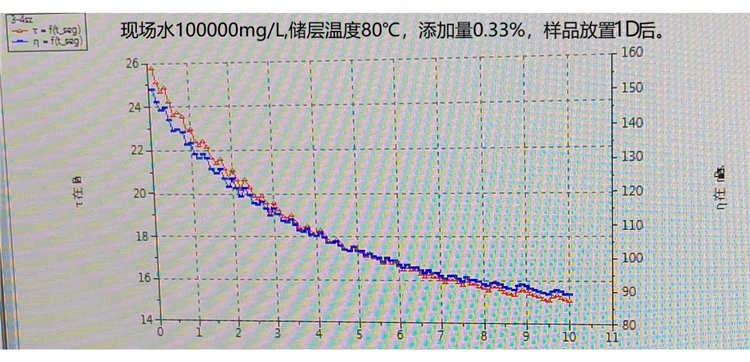

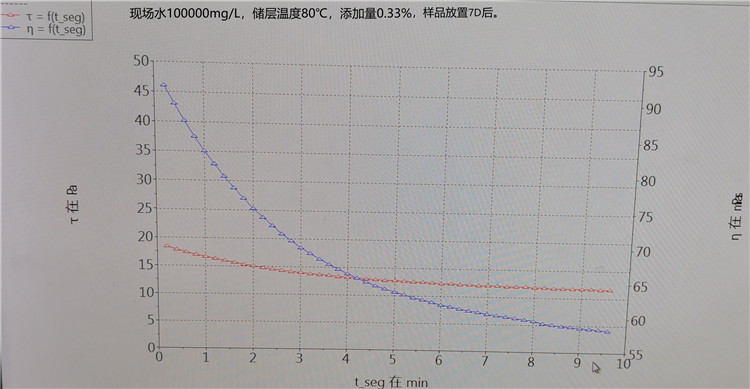

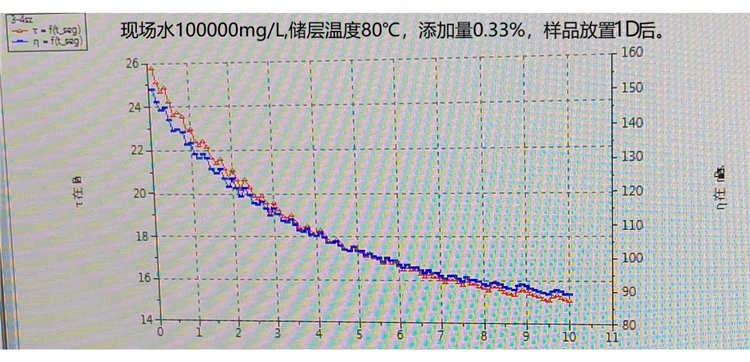

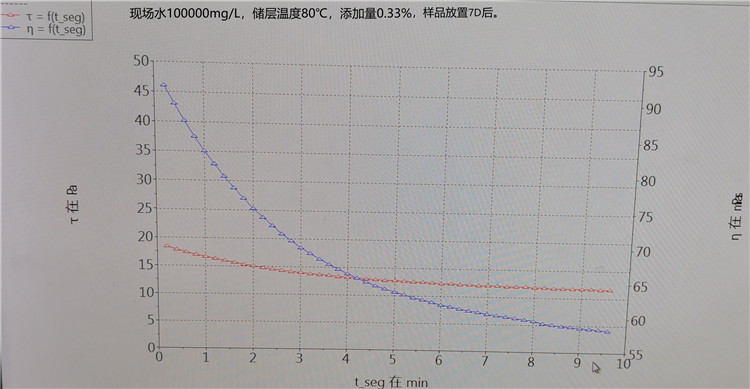

SDKX-6669 test results graph

Continuous viscosity reduction without rebound (after 1 day)

continuous viscosity reduction without rebound (after 3 days)

continuous viscosity reduction without rebound (after 7 days)

4. Recommended dosage: 0.33%~5%.

5. Packaging and storage: This product is packaged in plastic barrels or Tietong. The net content of each barrel is negotiated according to user requirements, and the net content tolerance meets JJF 1070-2005. The packaging barrel should be firm and leak-free, and other packaging methods can also be used according to user requirements.

Store in a ventilated and dry warehouse, and it is forbidden to place it near a heat source for a long time. The storage period is 20 months.

heavy oil cold production product innovation point: SDKX-6669 has dual functions of foaming and viscosity reduction under different oilfield reservoir temperatures, continuous viscosity reduction without rebound . Stability is better than conventional viscosity reducers.

- Overview and features

2. In the synthesis of SDKX-6669 product, the supermolecular viscosity-reducing active agent is used to graft the foaming tube energy group, which innovates both viscosity reduction and high foaming, which is suitable for heavy oil cold production air foam flooding, ensuring foam regeneration and performance The continuity and stability of the viscosity reduction system

3. The innovation of the SDKX-6669 product is to reduce the viscosity of Xinjiang oilfields with high temperature, high salinity, high salinity flowing heavy oil, and extra-heavy oil blocks mixed with thin oil, as well as conventional wellbore viscosity reduction. The difficult problems of fast viscosity reduction and fast viscosity rebound have synthesized a product that can continuously reduce viscosity without rebounding.

- Scope of application

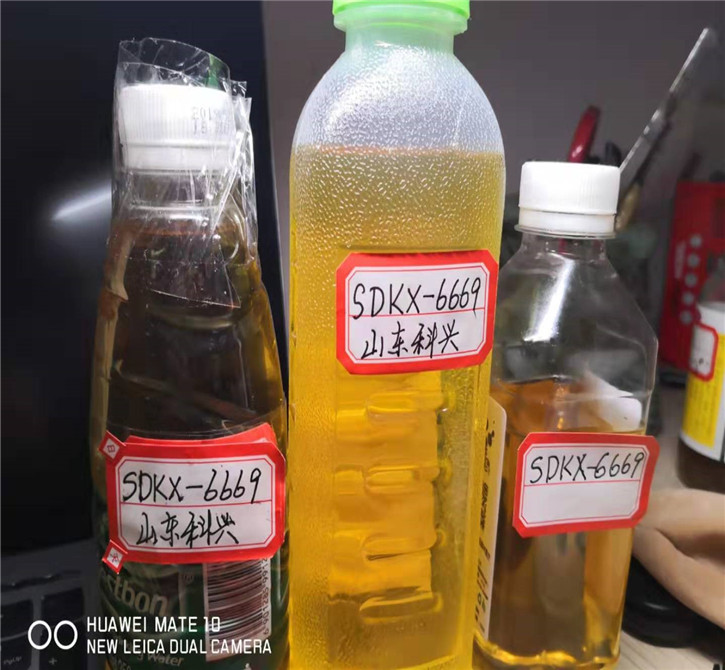

- skills requirement

| Item | Index |

| Appearance | Colorless to light brown liquid |

| PH value | 7~8 |

| Density (20℃, g/cm 3 ) | 0.8~1.100 |

| Viscosity reduction rate (add 0.35%),% | 40~70 |

| Foaming rate > | 389 |

SDKX-6669 test results graph

Continuous viscosity reduction without rebound (after 1 day)

continuous viscosity reduction without rebound (after 3 days)

continuous viscosity reduction without rebound (after 7 days)

4. Recommended dosage: 0.33%~5%.

5. Packaging and storage: This product is packaged in plastic barrels or Tietong. The net content of each barrel is negotiated according to user requirements, and the net content tolerance meets JJF 1070-2005. The packaging barrel should be firm and leak-free, and other packaging methods can also be used according to user requirements.

Store in a ventilated and dry warehouse, and it is forbidden to place it near a heat source for a long time. The storage period is 20 months.